- info@prototypeshlh.com

- +86-133-9285-9203

- Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

SERVICES

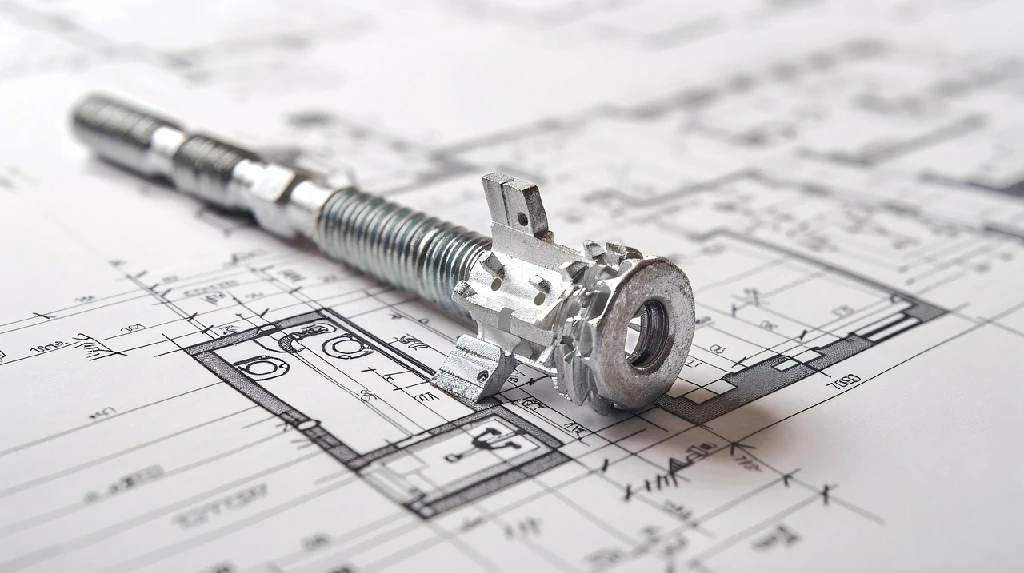

CNC Machining Service

Tight tolerances and finishing capabilities, as fast as 2 days.

Vacuum Casting Service

Production quality parts without the tooling investment.

Sheet Metal Fabrication

Experience the versatility 6 cost efficiency withflexible application options.

Die Casting Service

Create high quality custom mechanicals withprecision and accuracy.

Injection Molding Service

Production-grade steel tooling, as fast as weeks.

Carbon Fiber Manufacturing

Composite materials, such as carbon fiber reinforced plastics are highly versatile and efficiert materials.

Popular Services

Injection Molding Service

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 24 hours.

3D Printing Service

Our 3D printing solutions cater to personalised needs with a diverse range of materials and colour options, including SLA, SLS, FDM, Projet, DMLS, and MJF printing services.

Surface Finishing

The easiest way to source your custom parts, with 15+ surface finishing options.

Design Guide

In-depth design guides full of best practices for all of HLH's manufacturing processes.

Case Studies

Success stories from innovativecompanies using HLH.

Blog

lndustry trends, company news andproduct updates.

Featured Posts

Aerospace & UAV

HLH is your 3D manufacturing partner from prototype to large scale production.

Consumer Products

New Product Introduction Solutions for Consumer Products.

Automotive

New Product Introduction Solutions for Automotive.

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Communications

We understand the demands and ever changing landscape of the communications industry.

Product Development

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet.

Imagine designing a car cup holder with a complex, beautiful geometry. It looks perfect in the digital model. But when you go to manufacture it, the tooling costs $10,000, it requires a 5-part assembly, and the scrap rate is 30%. What went wrong?

The design was brilliant, but it wasn't manufacturable.

This is where Design for Manufacturing (DFM) comes in. DFM is the systematic engineering practice of designing products to optimize them for ease of manufacturing and assembly. It’s the crucial process of bridging the gap between a great idea and a viable, profitable product.

At its core, DFM is a proactive, collaborative process. It involves analyzing a product's design before any tooling is cut or production begins, with the explicit goal of:

DFM is not about compromising your design; it's about optimizing it for the real world of factories, machines, and human assemblers.

A successful DFM analysis rests on five fundamental principles. These should be considered simultaneously, not sequentially.

Ignoring DFM is a costly gamble. Implementing it yields clear, measurable returns:

Design for Manufacturing is more than a checklist; it is a fundamental shift in how we approach product development. It replaces the siloed, sequential process ("I design it, you figure out how to make it") with a collaborative, integrated one.

By embracing DFM, you stop designing for the virtual world and start designing for the real one. You transform your brilliant concept from a digital file into a successful physical product—efficiently, reliably, and profitably.

For CNC parts, DFM focuses on minimizing tool changes, avoiding deep cavities, and maintaining consistent wall thickness to improve machining efficiency.

In plastic molding, DFM emphasizes draft angles, uniform wall thickness, gate location, and material flow to ensure moldability and surface quality.

For additive manufacturing, DFM means optimizing part orientation, support structures, and layer thickness for better accuracy and reduced post-processing.

If you’re developing a new prototype or product, HLH engineering team can help you apply DFM best practices to turn your design into a successful reality. Contact us today to learn more about how DFM can improve your next project.

Emali: info@prototypeshlh.com