- info@prototypeshlh.com

- +86-133-9285-9203

- Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

SERVICES

CNC Machining Service

Tight tolerances and finishing capabilities, as fast as 2 days.

Vacuum Casting Service

Production quality parts without the tooling investment.

Sheet Metal Fabrication

Experience the versatility 6 cost efficiency withflexible application options.

Die Casting Service

Create high quality custom mechanicals withprecision and accuracy.

Injection Molding Service

Production-grade steel tooling, as fast as weeks.

Carbon Fiber Manufacturing

Composite materials, such as carbon fiber reinforced plastics are highly versatile and efficiert materials.

Popular Services

Injection Molding Service

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 24 hours.

3D Printing Service

Our 3D printing solutions cater to personalised needs with a diverse range of materials and colour options, including SLA, SLS, FDM, Projet, DMLS, and MJF printing services.

Surface Finishing

The easiest way to source your custom parts, with 15+ surface finishing options.

Design Guide

In-depth design guides full of best practices for all of HLH's manufacturing processes.

Case Studies

Success stories from innovativecompanies using HLH.

Blog

lndustry trends, company news andproduct updates.

Featured Posts

Aerospace & UAV

HLH is your 3D manufacturing partner from prototype to large scale production.

Consumer Products

New Product Introduction Solutions for Consumer Products.

Automotive

New Product Introduction Solutions for Automotive.

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Communications

We understand the demands and ever changing landscape of the communications industry.

Product Development

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet.

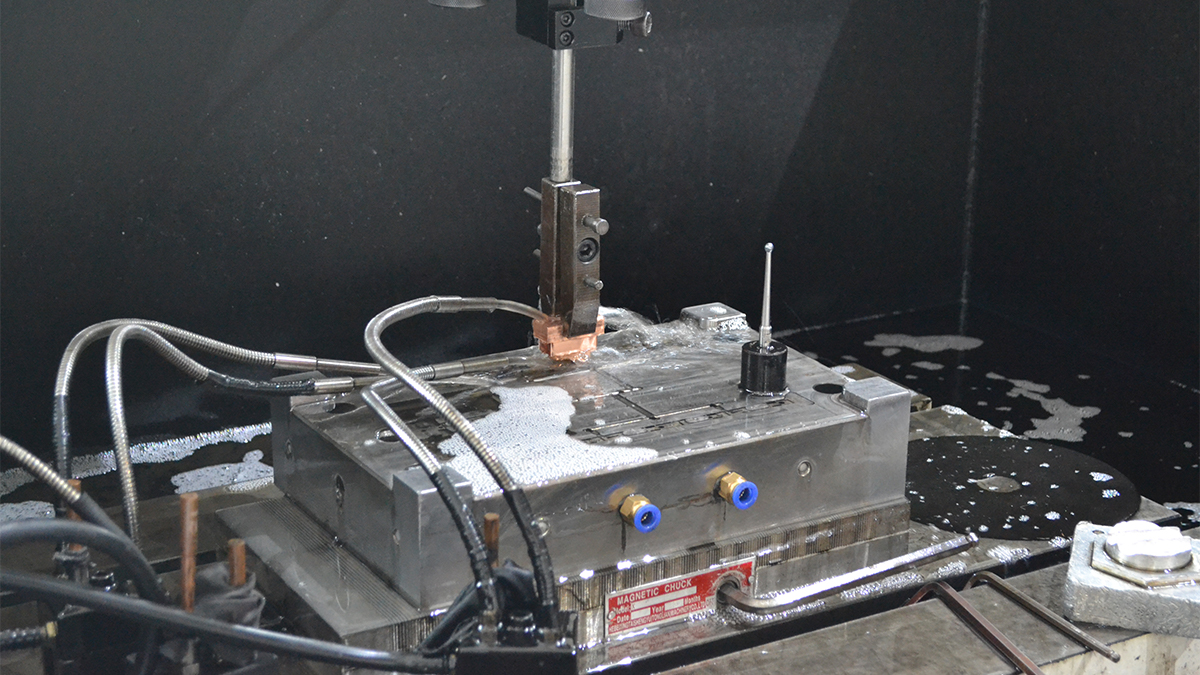

CNC (Computer Numerical Control) machining is a versatile and reliable manufacturing process that uses computer-guided tools to cut and shape materials into precise parts. Whether you need a single prototype or a small batch production run, CNC machining delivers consistent accuracy, fast turnaround, and excellent surface finish. In this article, we’ll explore what CNC machining is, its advantages, typical applications, and why choosing a professional CNC service can elevate your project.

In an era where microns define success, CNC machining remains the gold standard for creating high-performance prototypes and end-use parts. Whether you need a single functional prototype or 10,000 production units, our CNC services deliver the precision, speed, and quality that engineers trust to bridge R&D and manufacturing.

CNC machining involves programming a computer to control cutting tools—such as mills, lathes, and routers—to remove material from a solid block (metal, plastic, or composite) and create the desired shape. With multi-axis capabilities, CNC machines can produce complex geometries and fine details that are difficult to achieve through manual machining.

| Parameter | Capability | Your Advantage |

|---|---|---|

| Tolerance | ±0.01mm (ISO 2768-f) | Perfect fit for aerospace/medical |

| Machining Tech | 3/4/5-axis milling, Swiss turning | Complex geometries in single setup |

| Materials | 50+ metals/plastics (Al 7075, SS316L, PEEK, Titanium) | Right material for extreme conditions |

| Surface Finish | Ra 0.2μm (mirror) to bead blasting | Functional or cosmetic-ready parts |

| Max Part Size | 800 × 500 × 400 mm | Accommodates large industrial components |

Our ISO 9001-certified workshops use Mori Seiki & DMG machines with laser calibration. Every part undergoes 3-stage inspection:

1. In-process probing during machining

2. CMM verification (Zeiss Contura G2)

3. Final manual QC against GD&T drawings

Case Study: Reduced bearing housing rejection rate by 98% for automotive client through ±0.005mm bore tolerance control.

· Traceable certified materials (Mill certificates)

· Stress-relieving & heat treatment for critical components

· Micro-hardness testing on request

· Critical surfaces: Anodizing (Type II/III), Passivation, Ni-PTFE plating

· Aesthetic finishes: Powder coating, silk screening, laser engraving

· Functional treatments: Cryogenic processing for wear resistance

| Industry | Use Cases | Key Materials |

|---|---|---|

| Aerospace | Turbine blades, landing gear components | Inconel 718, Ti-6Al-4V |

| Medical | Surgical instruments, implant prototypes | PEEK, 316LVM, Cobalt Chrome |

| Automotive | Transmission housings, EV battery fixtures | Al 6061-T6, Magnesium alloys |

| Robotics | Actuator housings, precision gears | 7075 Aluminum, POM Delrin |

1. Zero-Tooling Cost: Ideal for 1 - 10,000+ units

2. DFM Optimization: Our engineers fix manufacturability issues pre-machining

3. Batch Consistency: <0.02% dimensional variance across production runs

4. Full Compliance: ITAR, ISO 13485, AS9100 options

Upload your STEP/IGES file and receive:

· Instant quoting within 1 hour

· Free DFM report with cost-saving redesign tips

· Material selection guidance from our engineers

CNC machining is a powerful tool for creating high-precision parts in a variety of industries. By partnering with a skilled CNC service provider, you can reduce development time, control costs, and achieve the exact specifications your project demands.

Ready to get started? Contact us today for a free quote on your CNC machining project.