- info@prototypeshlh.com

- +86-133-9285-9203

- Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

SERVICES

CNC Machining Service

Tight tolerances and finishing capabilities, as fast as 2 days.

Vacuum Casting Service

Production quality parts without the tooling investment.

Sheet Metal Fabrication

Experience the versatility 6 cost efficiency withflexible application options.

Die Casting Service

Create high quality custom mechanicals withprecision and accuracy.

Injection Molding Service

Production-grade steel tooling, as fast as weeks.

Carbon Fiber Manufacturing

Composite materials, such as carbon fiber reinforced plastics are highly versatile and efficiert materials.

Popular Services

Injection Molding Service

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 24 hours.

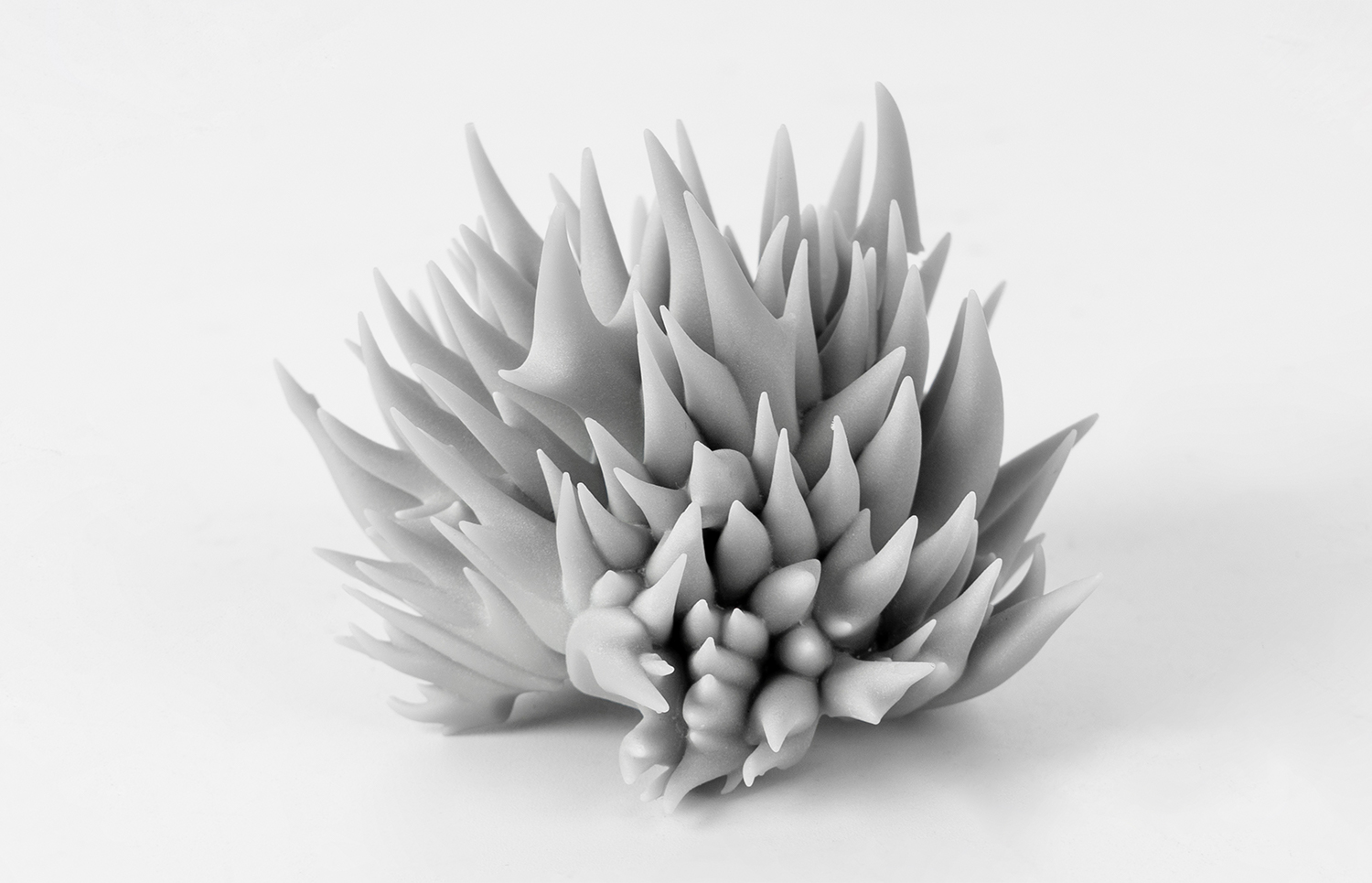

3D Printing Service

Our 3D printing solutions cater to personalised needs with a diverse range of materials and colour options, including SLA, SLS, FDM, Projet, DMLS, and MJF printing services.

Surface Finishing

The easiest way to source your custom parts, with 15+ surface finishing options.

Design Guide

In-depth design guides full of best practices for all of HLH's manufacturing processes.

Case Studies

Success stories from innovativecompanies using HLH.

Blog

lndustry trends, company news andproduct updates.

Featured Posts

Aerospace & UAV

HLH is your 3D manufacturing partner from prototype to large scale production.

Consumer Products

New Product Introduction Solutions for Consumer Products.

Automotive

New Product Introduction Solutions for Automotive.

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Communications

We understand the demands and ever changing landscape of the communications industry.

Product Development

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet.

When it comes to 3D printing, hitting “print” is only the last step of the process. If you want a part that’s strong, accurate, and actually looks great, you need to think about the entire journey—from design to finishing. Over the years, I’ve learned that a little extra attention to detail at each stage pays off big in the final result.

Here’s a practical, engineer-friendly guide to help you create your best 3D printed parts yet.

A great print starts long before the printer warms up.

Even the best design will fail if your printer isn’t dialed in.

Good prints start with good filament. Moisture is a silent killer—it causes stringing, poor layer bonding, and weak parts. Store your spools in airtight containers with desiccant, or use a filament dryer.

If you need strength, look into carbon-fiber-reinforced or glass-filled filaments.

It’s tempting to hit print and walk away, but even a quick mid-print check can save you hours. Warping, spaghetti failures, or clogged nozzles are much easier to fix early.

Your part may be functional out of the printer, but finishing steps can take it to the next level.

Perfect 3D printed parts aren’t about luck—they’re the result of good design, a well-tuned printer, quality materials, and some patience. Take the time to tweak, test, and improve with each project, and you’ll notice your parts getting better and better.

If you have 3D printing requirements, please contact us or view our 3D printing services. We have the easiest way to source high-quality 3D printed prototypes and production parts. ISO 9001, ISO 13485, and AS9100 certified.

Emali: info@prototypeshlh.com