- info@prototypeshlh.com

- +86-133-9285-9203

- Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

SERVICES

CNC Machining Service

Tight tolerances and finishing capabilities, as fast as 2 days.

Vacuum Casting Service

Production quality parts without the tooling investment.

Sheet Metal Fabrication

Experience the versatility 6 cost efficiency withflexible application options.

Die Casting Service

Create high quality custom mechanicals withprecision and accuracy.

Injection Molding Service

Production-grade steel tooling, as fast as weeks.

Carbon Fiber Manufacturing

Composite materials, such as carbon fiber reinforced plastics are highly versatile and efficiert materials.

Popular Services

Injection Molding Service

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 24 hours.

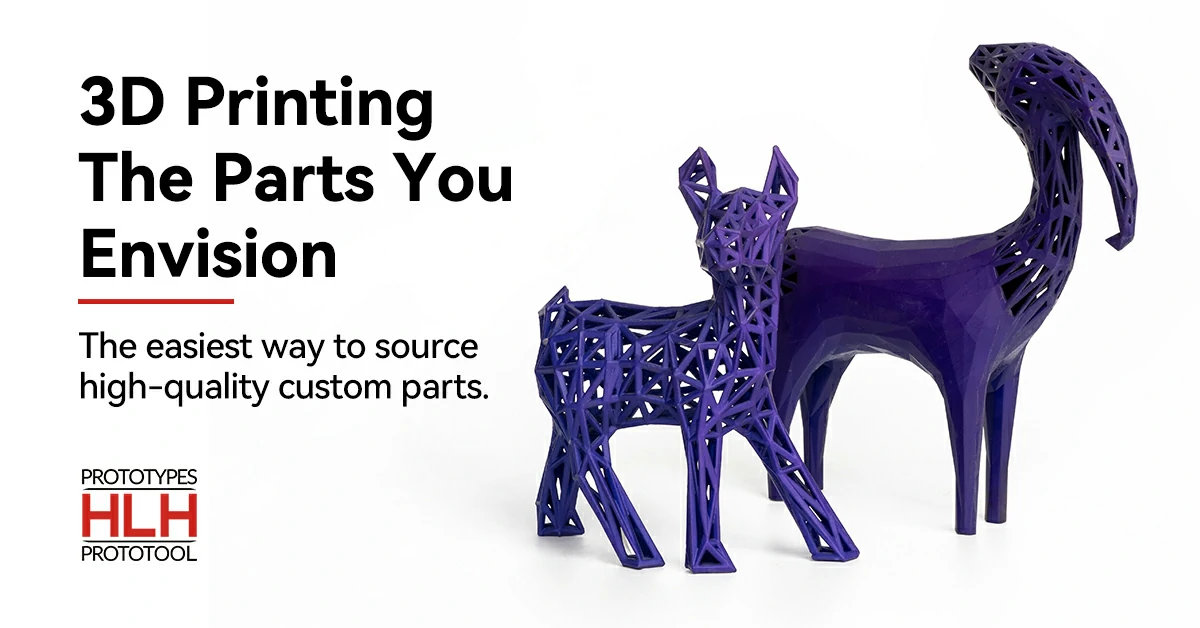

3D Printing Service

Our 3D printing solutions cater to personalised needs with a diverse range of materials and colour options, including SLA, SLS, FDM, Projet, DMLS, and MJF printing services.

Surface Finishing

The easiest way to source your custom parts, with 15+ surface finishing options.

Design Guide

In-depth design guides full of best practices for all of HLH's manufacturing processes.

Case Studies

Success stories from innovativecompanies using HLH.

Blog

lndustry trends, company news andproduct updates.

Featured Posts

Aerospace & UAV

HLH is your 3D manufacturing partner from prototype to large scale production.

Consumer Products

New Product Introduction Solutions for Consumer Products.

Automotive

New Product Introduction Solutions for Automotive.

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Communications

We understand the demands and ever changing landscape of the communications industry.

Product Development

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet.

Consumer product prototyping is the process of creating physical models or functional samples of a product before mass production. It allows designers, engineers, and companies to test design, functionality, and manufacturability before investing in expensive tooling and large-scale production.

Prototyping plays a vital role in modern product development, especially for startups and brands launching new consumer electronics, smart devices, home products, or wearable technology.

HLH Consumer Product Prototype

A prototype allows you to verify whether the design works in real-world conditions. It helps identify design flaws, structural issues, or usability problems early.

Functional prototypes help engineers test assembly, strength, and performance. Adjustments can be made before moving to production, saving both time and cost.

Without prototyping, companies risk expensive redesigns after tooling. Prototyping ensures the design is ready for production.

High-quality prototypes can be used for:

3D printing is one of the fastest ways to create product prototypes.

Best for:

Materials include:

CNC machining produces high-precision prototypes using real production materials.

Best for:

Common materials:

Vacuum casting is ideal for low-volume production and appearance models.

Advantages:

For products nearing mass production, prototype injection molding helps verify tooling and part quality before full-scale manufacturing.

Material selection depends on the product’s function and target market.

Plastic Prototypes

Metal Prototypes

Using production-grade materials ensures accurate testing results.

A successful product moves through several stages:

Working with an experienced manufacturer ensures a smooth transition from prototype to production.

When selecting a manufacturing partner, consider:

A professional prototyping manufacturer can help optimize design, reduce costs, and accelerate product launch.

Consumer product prototyping is a crucial step in turning ideas into successful market-ready products. From design validation to functional testing and low-volume production, the right prototyping strategy helps startups and brands reduce risks, control costs, and launch faster.

By choosing the right manufacturing processes and experienced partners, companies can confidently move from concept to mass production and stay competitive in today’s fast-paced product market.

Contact us today for a free quote on your consumer product project.

Emali: info@prototypeshlh.com

Phone: +86-133-9285-9203