- info@prototypeshlh.com

- +86-133-9285-9203

- Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

SERVICES

CNC Machining Service

Tight tolerances and finishing capabilities, as fast as 2 days.

Vacuum Casting Service

Production quality parts without the tooling investment.

Sheet Metal Fabrication

Experience the versatility 6 cost efficiency withflexible application options.

Die Casting Service

Create high quality custom mechanicals withprecision and accuracy.

Injection Molding Service

Production-grade steel tooling, as fast as weeks.

Carbon Fiber Manufacturing

Composite materials, such as carbon fiber reinforced plastics are highly versatile and efficiert materials.

Popular Services

Injection Molding Service

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 24 hours.

3D Printing Service

Our 3D printing solutions cater to personalised needs with a diverse range of materials and colour options, including SLA, SLS, FDM, Projet, DMLS, and MJF printing services.

Surface Finishing

The easiest way to source your custom parts, with 15+ surface finishing options.

Design Guide

In-depth design guides full of best practices for all of HLH's manufacturing processes.

Case Studies

Success stories from innovativecompanies using HLH.

Blog

lndustry trends, company news andproduct updates.

Featured Posts

Aerospace & UAV

HLH is your 3D manufacturing partner from prototype to large scale production.

Consumer Products

New Product Introduction Solutions for Consumer Products.

Automotive

New Product Introduction Solutions for Automotive.

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Communications

We understand the demands and ever changing landscape of the communications industry.

Product Development

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet.

Machining is the controlled process of removing material from a workpiece to achieve a desired geometry, size, and surface finish. It is a foundational discipline within manufacturing, enabling the production of high-precision components for industries ranging from aerospace and automotive to medical devices and consumer electronics. At its core, machining transforms raw materials—typically metals, plastics, or composites—into functional parts through subtractive methods, where material is selectively removed.

The selection of a machining process is governed by a critical balance of several factors: the dimensional and geometric tolerances required, the material properties of the workpiece, the desired surface integrity, production volume and cost targets, and the available equipment. No single process is optimal for all scenarios; a deep understanding of each method's capabilities and limitations is essential for efficient and effective manufacturing.

Subtractive processes, where material is removed via cutting tools, form the backbone of traditional machining.

Turning is performed on a lathe, where the workpiece rotates at high speed (the primary motion), and a stationary cutting tool is fed into it (the secondary feed motion).

Ideal For: Primarily for generating axisymmetric (rotationally symmetric) parts.

Primary Machine: Lathe or CNC Turning Center.

Typical Tolerances: Can hold tight tolerances, often within ±0.025 mm (±0.001") for CNC turning.Common

Applications: Shafts, pins, bushings, engine cylinders, and any component with a cylindrical profile.

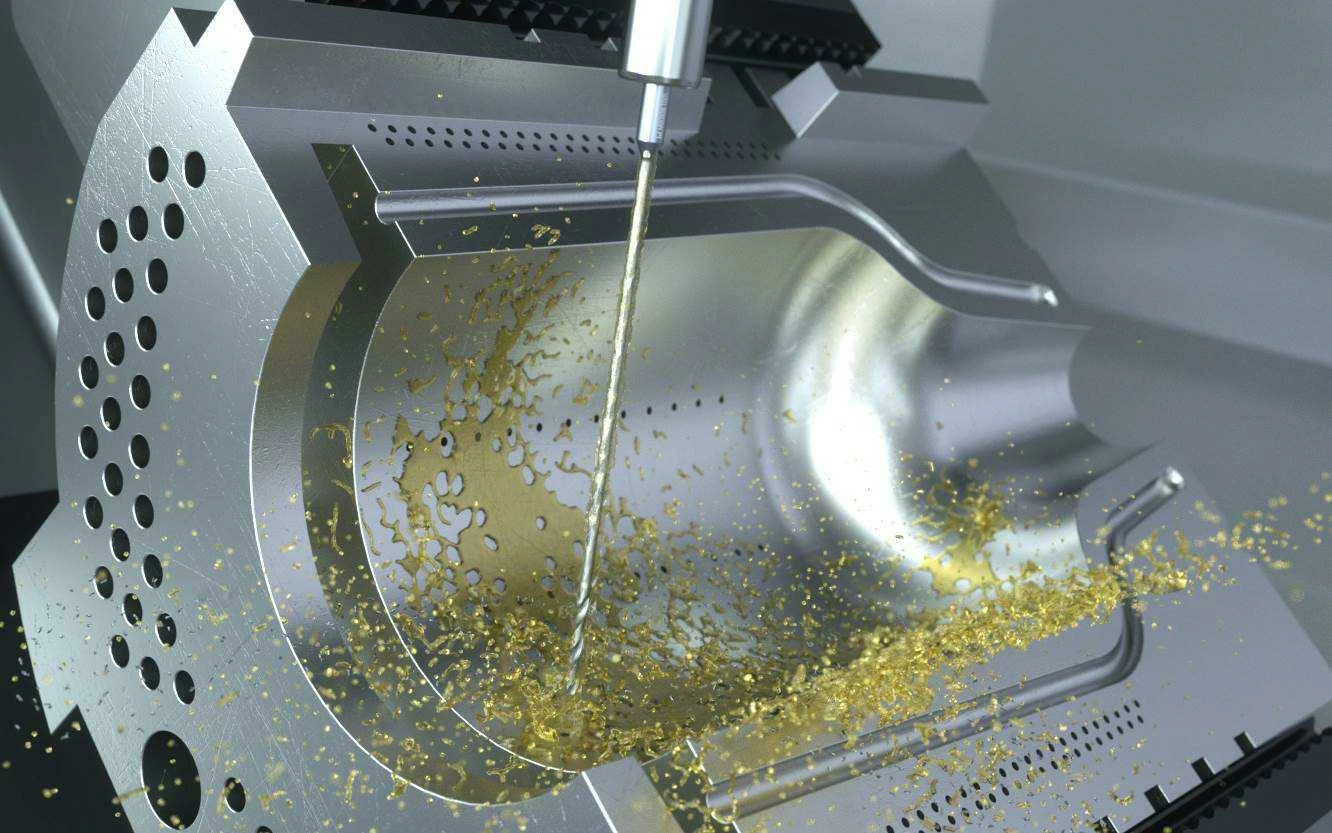

Milling employs a rotating multi-point cutting tool. The workpiece is secured to a table that moves in multiple axes relative to the tool.

Peripheral/Plain Milling: The tool's axis is parallel to the workpiece surface. Used for slab milling and slotting.

Face Milling: The tool's axis is perpendicular to the workpiece surface, using teeth on the tool's periphery and face to create flat surfaces.

End Milling: A versatile tool used for profiling, slotting, pocketing, and contouring.

Form Milling: Uses shaped tools to create complex contours like gears or grooves.

Ideal For: Creating complex 2D and 3D geometries, flat surfaces, pockets, slots, and intricate contours.

Primary Machine: Milling Machine or CNC Machining Center (Vertical/Horizontal).

Typical Tolerances: Similar to turning, with CNC mills capable of ±0.025 mm (±0.001") or better.

Common Applications: Engine blocks, mold cavities, brackets, structural components, and enclosures.

| Process | Material Removal Mechanism | Primary Motion | Key Output Geometries |

|---|---|---|---|

| Turning | Single-point cutting tool | Workpiece rotation | Cylindrical, conical, faced surfaces |

| Milling | Multi-point rotating tool | Tool rotation | Flat surfaces, slots, pockets, complex 3D contours |

Drilling creates round holes using a rotating drill bit, typically a twist drill with two cutting edges. It is often a preliminary step for other operations like reaming or tapping.

Chip Evacuation: Critical for deep holes to prevent tool breakage.

Hole Accuracy: Standard drilling provides limited accuracy and surface finish. For higher quality, subsequent operations like reaming (for size/roundness) or boring (for precise diameter/position) are used.

Related Process: Tapping: The process of cutting internal threads inside a hole using a tap tool.

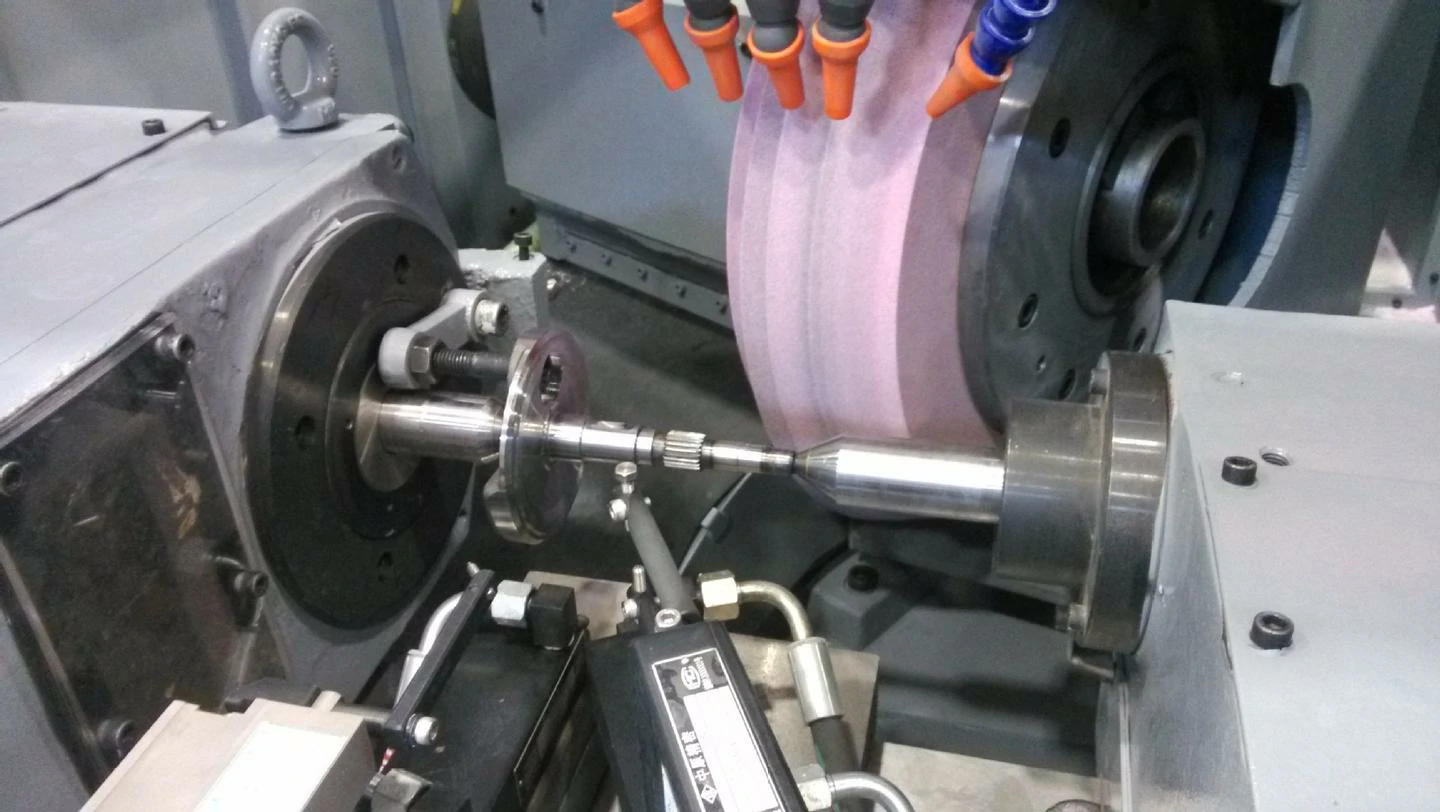

Grinding is an abrasive machining process that uses a rotating wheel composed of abrasive grains (e.g., aluminum oxide, silicon carbide, diamond) as the cutting tool. It is primarily a finishing process.

Surface Grinding: Produces a flat, smooth surface.

Cylindrical Grinding: For finishing the external or internal diameter of cylindrical parts.

Centerless Grinding: For high-volume production of small cylindrical parts without using centers for fixation.

(CNC Grinding)

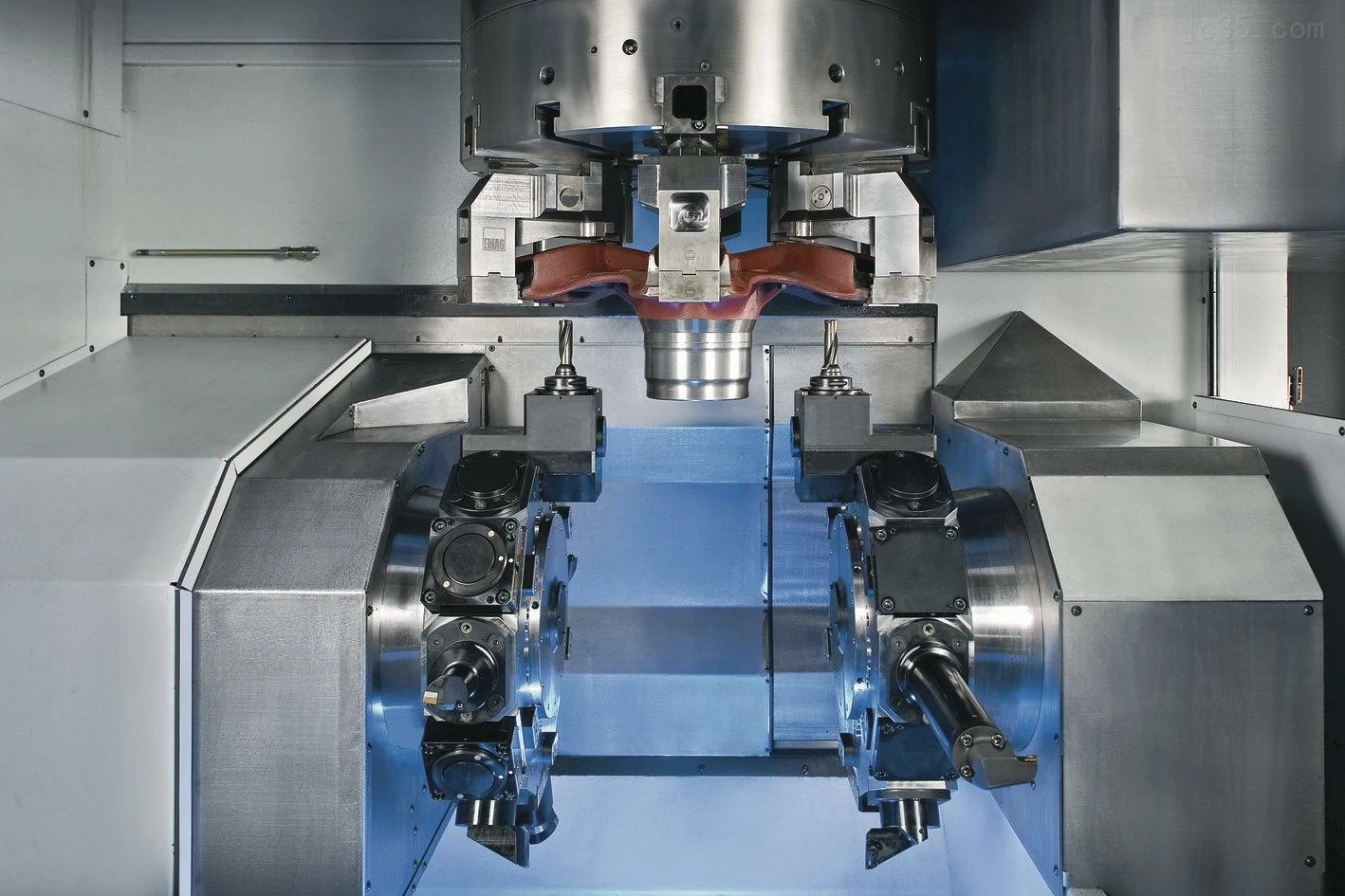

Broaching is a highly efficient process for machining complex internal or external profiles using a multi-toothed tool called a broach.

High Productivity: Completes complex shapes in one linear stroke, making it extremely fast for high-volume production.

Excellent Surface Finish: Produces fine finishes due to the shearing action of its finishing teeth.

CNC Integration: Modern CNC broaching machines provide precise control over stroke speed, force, and tool positioning, allowing for flexible automation and quick changeovers.

Specialized Tooling: Broaches are complex, custom-made tools, making the process most economical for large batch sizes.

(CNC Broaching)

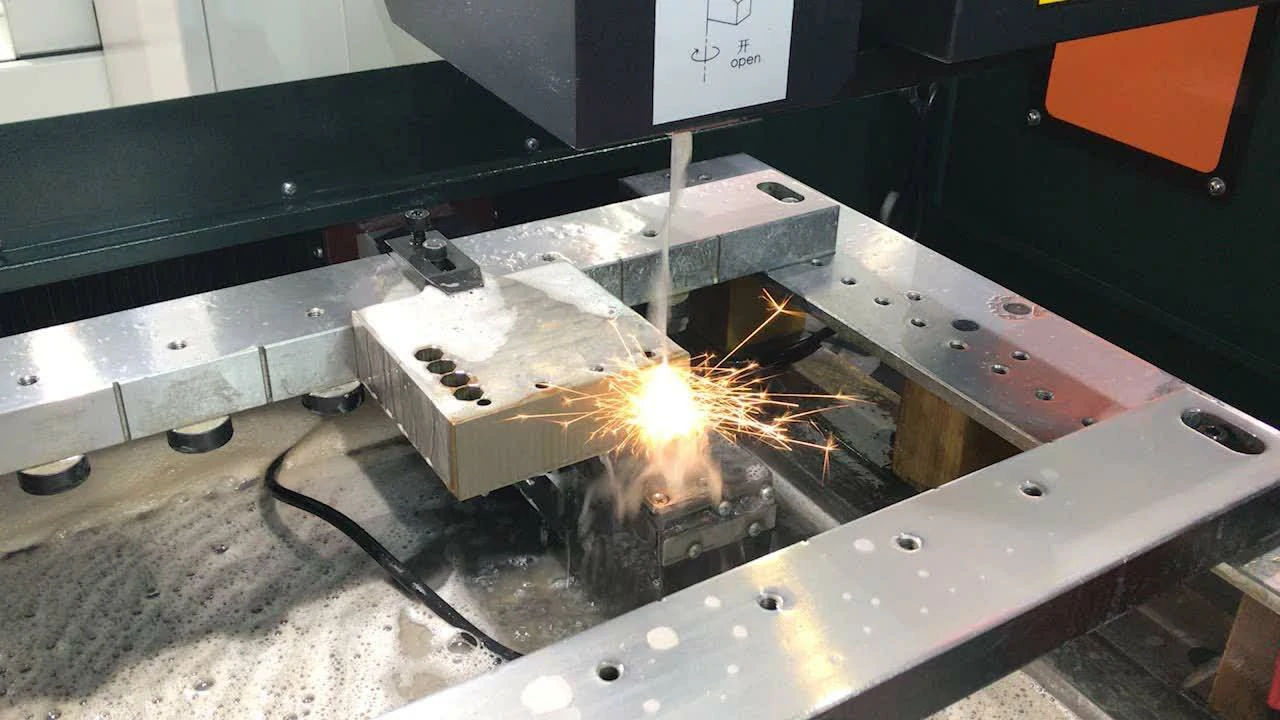

EDM is a non-traditional, thermoelectric process that removes material by generating a series of controlled electrical sparks between an electrode and a conductive workpiece.

Sinker EDM (Ram EDM): Uses a pre-shaped, often graphite or copper, electrode to create a negative imprint in the workpiece. Ideal for complex cavities, molds, and dies.

Wire EDM: Uses a thin, continuously fed brass or coated wire as the electrode to cut intricate 2D and 3D profiles through the workpiece like a precision bandsaw. Capable of extreme accuracy and fine details.

Material Independence: Can machine any electrically conductive material, regardless of its hardness (e.g., hardened tool steel, titanium, carbides).

No Mechanical Force: Since there is no contact, delicate parts and fine features can be machined without distortion.

| Process | Mechanism | Key Strength | Typical Application |

|---|---|---|---|

| CNC Boring | Single-point cutting on internal diameters | Ultra-precise hole size, position & finish | Engine blocks, precision bearing seats |

| CNC Broaching | Linear cutting with incremental teeth | High-speed production of complex internal shapes | Internal splines, keyways, gear teeth |

| EDM | Thermal erosion by electrical sparks | Machining hard materials & intricate geometries without tool force | Mold cavities, hardened steel dies, micro-components |

(Electrical Discharge Machining (EDM))

These processes are used for materials or geometries that challenge conventional methods.

Ideal For: Machining extremely hard, conductive materials and creating intricate cavities or sharp internal corners impossible with milling.

Ideal For: Precise 2D profiling of sheet metal, plastics, and composites. Excellent for prototyping and complex contours.

Ideal For: Cutting materials sensitive to high temperatures (no heat-affected zone), such as certain plastics, composites, or laminated metals.

Choosing the optimal manufacturing process is a systematic decision. Consider the following hierarchy:

1. Part Geometry & Complexity: Is it rotational (favor turning) or prismatic (favor milling)? Does it have deep internal features (consider EDM) or is it a flat pattern (laser/waterjet)?

2. Material: Hardened steel may require grinding or EDM after heat treatment. Brittle ceramics often need abrasive or non-traditional processes.

3. Dimensional Tolerance and Surface Finish Requirements: Ultra-fine tolerances and finishes necessitate grinding or honing as a final operation.

4. Production Volume and Cost: High volumes justify the high initial cost of forging dies or casting molds. Low volumes or prototypes favor flexible processes like CNC machining or laser cutting.

5. Part Function and Mechanical Properties: Critically loaded parts benefit from the superior grain structure of forgings.

In practice, a finished component is often the result of a multi-process manufacturing plan. A common route might be: Casting or Forging (to create a near-net-shape blank) → CNC Turning and/or Milling (to achieve critical dimensions and features) → Heat Treatment (to enhance material properties) → Grinding (to finalize key surfaces and tolerances).

By understanding the distinct roles, advantages, and constraints of each family of machining processes, engineers and manufacturers can develop efficient, cost-effective, and reliable production strategies, transforming design intent into physical reality.

Contact us today for a free quote on your CNC machining project.

Emali: info@prototypeshlh.com

Phone: +86-133-9285-9203