- info@prototypeshlh.com

- +86-133-9285-9203

- Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

SERVICES

CNC Machining Service

Tight tolerances and finishing capabilities, as fast as 2 days.

Vacuum Casting Service

Production quality parts without the tooling investment.

Sheet Metal Fabrication

Experience the versatility 6 cost efficiency withflexible application options.

Die Casting Service

Create high quality custom mechanicals withprecision and accuracy.

Injection Molding Service

Production-grade steel tooling, as fast as weeks.

Carbon Fiber Manufacturing

Composite materials, such as carbon fiber reinforced plastics are highly versatile and efficiert materials.

Popular Services

Injection Molding Service

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 24 hours.

3D Printing Service

Our 3D printing solutions cater to personalised needs with a diverse range of materials and colour options, including SLA, SLS, FDM, Projet, DMLS, and MJF printing services.

Surface Finishing

The easiest way to source your custom parts, with 15+ surface finishing options.

Design Guide

In-depth design guides full of best practices for all of HLH's manufacturing processes.

Case Studies

Success stories from innovativecompanies using HLH.

Blog

lndustry trends, company news andproduct updates.

Featured Posts

Aerospace & UAV

HLH is your 3D manufacturing partner from prototype to large scale production.

Consumer Products

New Product Introduction Solutions for Consumer Products.

Automotive

New Product Introduction Solutions for Automotive.

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Communications

We understand the demands and ever changing landscape of the communications industry.

Product Development

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet.

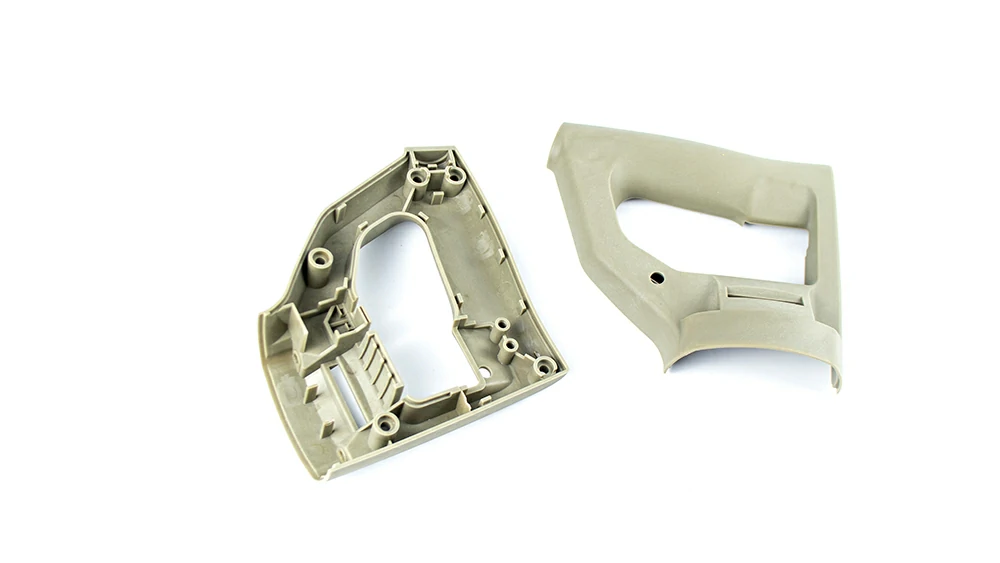

Injection molding is a well-established and highly efficient manufacturing process that injects molten plastic into molds to rapidly produce parts with excellent precision and surface finish. It’s widely used across industries like consumer electronics, automotive, and medical devices.

Once the mold is created, cycle times can be as fast as 10 seconds. Especially with multi-cavity molds, a single production cycle can yield multiple parts, dramatically lowering the cost per part.

Injection molding consistently delivers parts with tight tolerances. It’s ideal for mass production where uniformity across thousands—or even millions—of units is essential.

The process supports over 25,000 engineering-grade materials—including plastics, liquid silicone, and composites—with virtually unlimited color and performance customization.

Compared to many other manufacturing methods, injection molding generates very little waste. Excess material like runners and sprues is often recycled back into production.

With high-pressure molding, injection molding can produce intricate designs and fine surface detail that are difficult—or impossible—with other methods.

HLH Injection molding production

Mold production can take several weeks (especially for steel molds) and may cost more upfront—making it better suited for medium to large production runs.

To achieve optimal results, designs should account for uniform wall thickness, appropriate draft angles, and avoid undercuts unless side actions are used.

For small batch or prototyping, aluminum molds offer faster, more cost-effective options. High-volume projects benefit from hardened steel molds with multi-cavity designs.

Conformal cooling involves strategically placing cooling channels that precisely follow the part’s shape, rather than using straight-drilled paths.

HLH Injection machine

Injection molding offers high-speed, high-quality, and scalable production—especially perfect for large-volume runs. With an extensive material palette and fine detail capabilities, it’s versatile, efficient, and cost-effective. While initial costs and design constraints exist, thoughtful planning and advanced techniques like conformal cooling can unlock even greater performance.

Need a free quote? Email: info@prototypeshlh.com to speak with a member of our team.